Equipment Overview

Our facility is equipped with advanced machinery and tools, enabling efficient production and high-quality output.

Haas VVF4

The Haas VVF4 is engineered for precision machining, offering robust performance for complex part production.

Haas VF3

Ideal for versatile machining tasks, the Haas VF3 provides exceptional accuracy and reliability.

Haas VF2

The Haas VF2 delivers high-speed milling capabilities, ensuring efficient and precise operations.

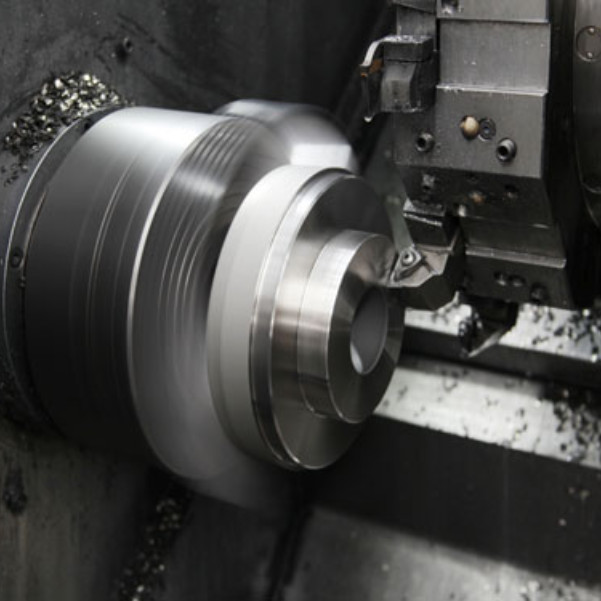

OKUMA ESL 10

OKUMA ESL 10 offers advanced lathe functionalities for precise and efficient metalworking.

OKUMA LB15

The OKUMA LB15 is known for its durability and precision in turning operations.

OKUMA LB25

This machine provides high-performance turning solutions for intricate parts.

AUTOMATIC SAW, vibratory de-burr machines

Our automatic saws and vibratory de-burr machines ensure smooth finishes and precise cuts for all materials.

MANUAL LATHES

Manual lathes are utilized for custom, precision-driven tasks requiring expert craftsmanship.

MANUAL MILL

Our manual mills provide the versatility needed for unique and specialized milling operations.